What is thread rolling machine?

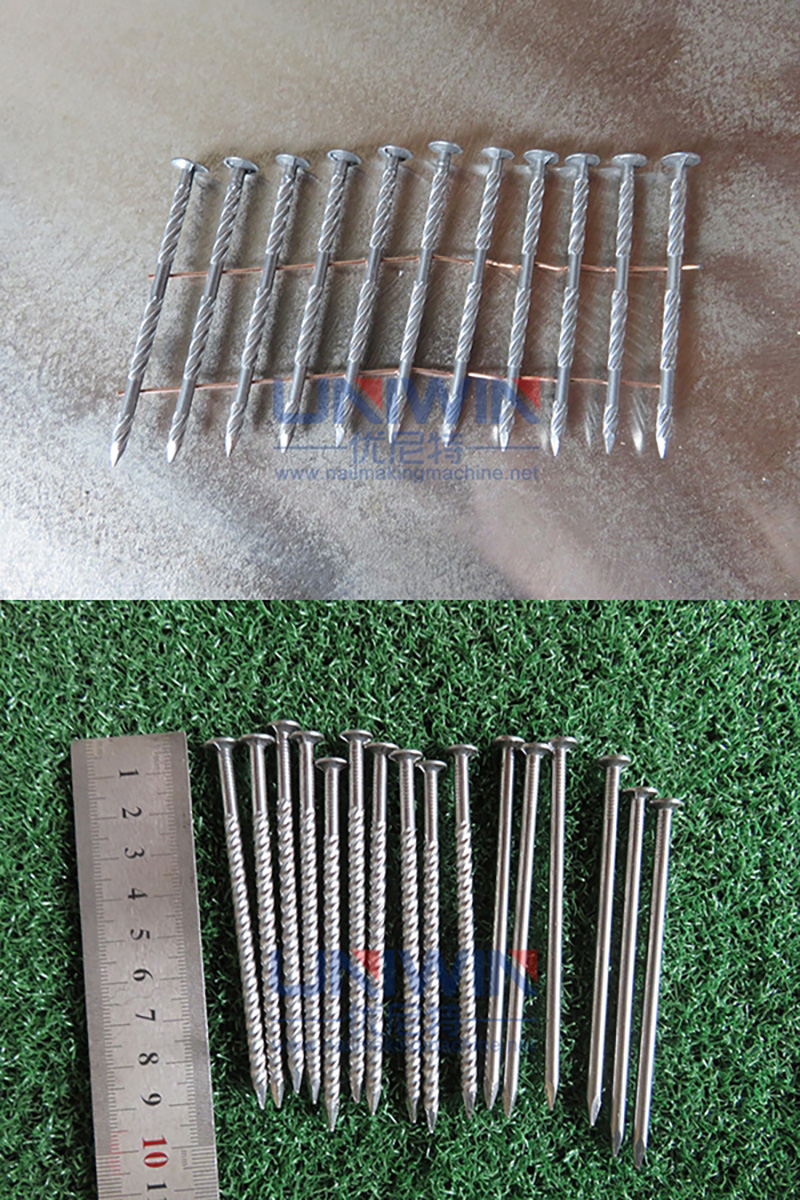

The thread rolling machine is a specialized equipment used in manufacturing to create threads on workpieces, such as screws, bolts, studs, and other metal fasteners. The machine can make screw shank, ring shank and spiral shank nails, and play an essential role in producing coil nails with the coil nail making machine. Instead of traditional methods of cutting threads, thread rolling adopts a cold working technology to squeeze fasteners between two thread rolling dies to form the threads without wearing out. The machine is equipped with a vibration plate and consists of four parts: a vibrating feeding system, rolling forming system, central drive system and electrical control system. Several advantages include cost savings, superior quality and convenient operation.

The uniwin brand automatic thread rolling machine is widely sold in many foreign countries, such as the US, Middle East, Europe, India, Saudi Arabia, Turkey, etc., and enjoys a good reputation for high-quality products and good after-sales service.

Parameters of thread rolling machine

| No. | Item | Specification |

|---|---|---|

| 1 | Model | GS-80 |

| 2 | Nail Length | 25-90mm |

| 3 | Max Thread Length | 76mm |

| 4 | Nail Diameter | 1.8-4.5mm |

| 5 | Speed | Max 1200pcs/min |

| 6 | Power | 7.5kw |

| 7 | Machine Weight | 1300kg |

| 8 | Machine Size | 1200*1200*1400mm |

Note: This is the most commonly used model, and if you have special requirements for making larger size fasteners, we can also customize the machine to meet your needs.

Quick-Wear Parts List of Thread Rolling Machine

| No. | Item | Life Time | Material/ Model |

|---|---|---|---|

| 1 | Thread Rolling Die | 6 Months | Alloy/Cold mould steel |

| 2 | Magnetic plate | 6 Months | Moulds steel |

| 3 | Nails push plate | 6 Months | Moulds steel |

| 4 | Sensor | 12 Months | M18,NPN |

| 5 | Relay | 12 Months | DC24,10A |

| 6 | Spring | 12 Months | Spring steel |

| Remarks:Item 2,3,4,5,6, each 2 pcs comes with machines for free. | |||

What is thread rolling?

Thread rolling is a highly efficient and precise method for producing threads on various fasteners and threaded components. It is a cold forming process, making the threads stronger than cutting. As the fastener is fed between the two thread rolling dies, they exert pressure to cause the material to deform and flow into the die’s thread profile, therefore forming the threads. This method produces the threads without removing any material.

What are the benefits of thread rolling compared to conventional thread cutting?

- Strength: Threads produced by thread rolling have a better grain flow, which enhances their tensile strength and fatigue resistance compared to cut threads.

- Highly accurate threads: The thread profile is formed by displaced metal rather than cutting away material, allowing for greater precision. And the thread rolling dies are made from hardened tool steel and can be ground to exact thread profiles and tolerances.

- High Efficiency: The process is faster and more efficient than cutting threads, especially for high-volume production.

- Surface Finish: Rolled threads have a smooth finish, reducing friction and improving the assembly of threaded parts.

- Material Savings: There’s minimal waste since material is displaced rather than removed.

Factory show

Thread roller application

The automatic thread rolling machine is commonly used in industries where threaded fasteners are essential, such as automotive, aerospace, construction, and manufacturing. It is particularly beneficial for mass production.

Thread rolling machine price

Uniwin brand thread rolling machine price is USD 5000-7000.

Thread rolling machine price in India

The thread rolling machine price in India is INR 416,050-582,471.