Nail Thread Shank Forming Mold/Thread Rolling Die: Key Components of the Thread Rolling Machine for Coil Nail Manufacturing

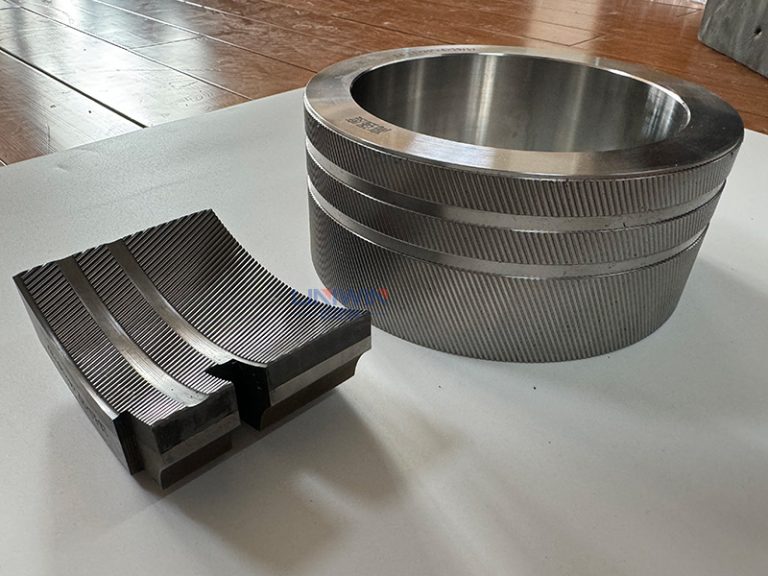

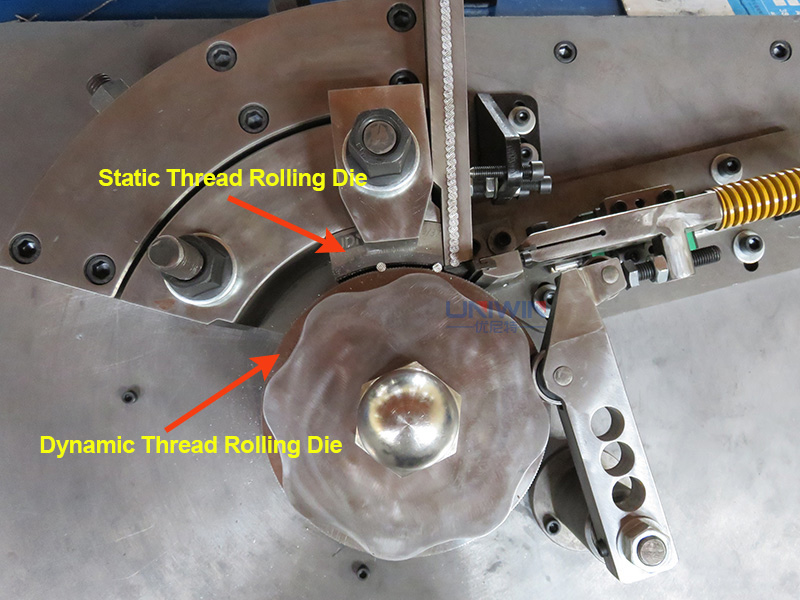

The thread rolling die is an essential core component of the thread rolling machine and plays a vital role in manufacturing metal fasteners such as coil nails. It forms screw threads or ring threads on fasteners like nails and screws through a cold rolling process without material loss. The thread rolling die usually consists of a dynamic rolling die and a static rolling die. The dynamic die applies pressure to nails by rotating to press the thread, while the static die remains fixed to provide the necessary support. This nail thread shank forming mold can be used for high-speed thread rolling machines and common thread rolling machines.

Finished Nails from Thread Rolling Machine

Flexibility of Thread Rolling Dies in Processing Different Nail Diameters

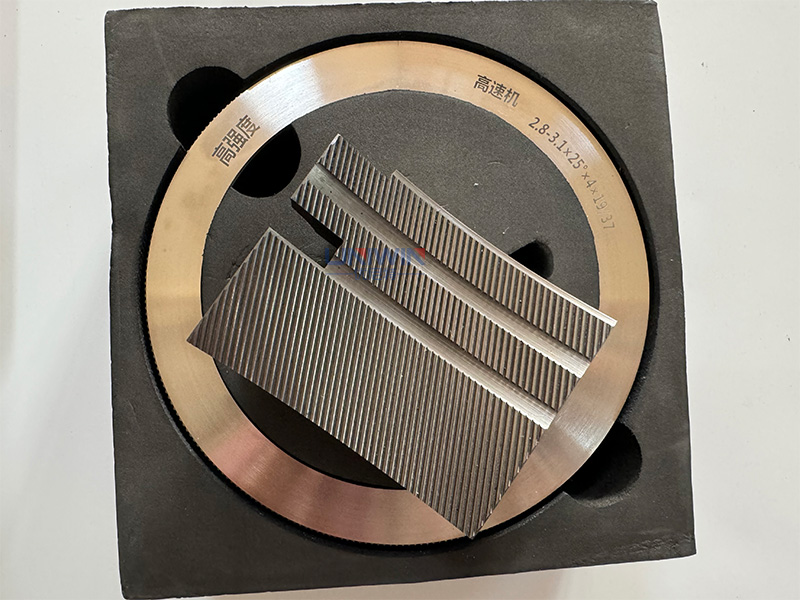

Thread rolling dies come in various sizes and can process nails of different diameters within a specific range, allowing flexibility in production. Typically, one rolling die can accommodate an increase or decrease in nail diameter of approximately 10%. For example, a die designed to process 2.1 mm diameter nails can also be used to process both 2.0 mm and 2.2 mm diameter nails.

Thread Rolling Die Materials and Durability

Thread rolling dies are usually made from alloy steel or cold-working die steel, known for their wear resistance and ability to maintain thread profile accuracy during high-intensity and high-speed production. The average service life of the die is about six months, but this varies depending on the production efficiency, the processed material characteristics, and the maintenance level. Especially in high-speed thread rolling machines, due to the high processing speed, the die is subjected to greater wear. Therefore, proper maintenance and care, such as regular lubrication and cleaning, are essential to extend the die lifespan and ensure consistent production quality.