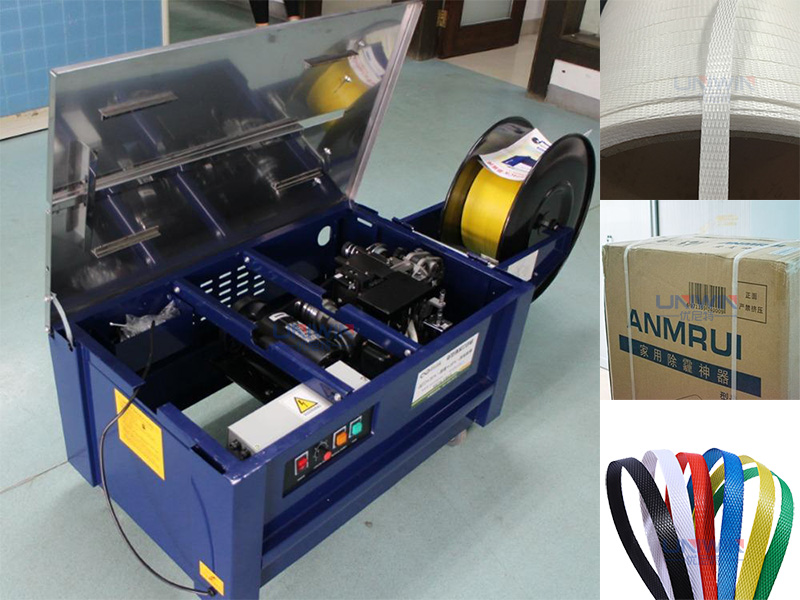

Low Table Semi-Automatic Strapping Machine

This low-table semi-automatic strapping machine is an efficient, durable, and cost-effective industrial packaging equipment, ideal for a wide range of applications, including hardware accessories, food box packaging, logistics, and express delivery industries, effectively meeting diverse packaging requirements.

Supporting PP strapping bands with widths of 6-15mm and thicknesses of 0.5-0.8mm (3000 meters per roll, 10 kg weight), this machine accommodates items of all sizes without restriction. Workers only need to strap the items manually, and the machine will automatically complete the strapping, hot melting, and cutting processes at a packaging speed of up to 1.5 meters per second.

The body is constructed from high-quality, robust materials with core motors and precision components to ensure long-term stability and reliable performance. The low-table design is particularly well-suited for handling and strapping large or heavy items, making it an ideal choice for businesses looking to optimize packaging efficiency and streamline operations.

Specification of Semi-Automatic PP Band Strapping Machine

| Item | Parameters |

|---|---|

| Model | Low Table Semi-Automatic Strapping Machine |

| Power Supply | 220V, 250W |

| Packing Speed | 1.5m/s |

| Maxi Packaging Size | Unlimited |

| PP Belt Thickness | 0.5-0.8mm |

| PP Belt Width | 6-15mm |

| Machine Weight | 85kg |

| Machine Size | 1600×570×450mm |

PP Strapping Band for Semi-Automatic Packaging Machine (Low Table Type)

PP strapping band (Polypropylene Strapping Band) is a cost-effective packaging material made of polypropylene (PP) and is widely used in semi-automatic, and fully automatic strapping machines. It features a thickness of 0.5-0.8mm, a width of 6-15mm, and a single roll length of up to 3000 meters, weighing approximately 10 kg. The PP band features a smooth surface, stable tension, and excellent hot melt performance, suitable for diversified packaging needs such as carton packaging, logistics express, industrial packaging, etc.

Note: To ensure the best use effect, please store it in a dry environment, avoid direct sunlight and high temperature.

Key Features of the Semi-Automatic Strapping Machine

Nut Adjustment + Widened Roller Head: When the thickness of the strapping band is inconsistent, the nut adjustment and widened roller head design can be used to ensure that the packaging is more solid and stable.

Simple Operation Panel: With simple settings, you can operate it proficiently in five minutes.

Function Buttons:

- Power Switch: Control the power of the machine.

- Band Outlet Meter Knob: Adjust the length of the strapping band.

- Band Cutting Switch: Start the strapping operation.

- Band Feeding Switch: Control the delivery of the strapping band.

Metal Panel: The body adopts a stainless steel panel, which has a neat and durable appearance. With the thickened casing, the load-bearing capacity is greatly increased.

Large Motor: Using a large motor, the running speed is faster, the machine life is extended, and the packaging effect is stable.

Strapping Band Tightness Adjustment: The tension of the strapping band can be easily adjusted according to the needs of different items to ensure that the items are firmly tied.

Wear-Resistant Gear + Swivel Caster:

- Wear-Resistant Gear: Improve gear durability and extend the working life of the machine.

- Swivel Caster: Facilitate the movement of the strapping machine, making operation more flexible and more applicable