WZ94-4A Automatic Roofing Nail Making Machine

Compared with wire nails, umbrella head roofing nails have higher profit and less competition, while it need higher skill to produce roofing nails.

The roofing nail making machine is also different with wire nail making machine, which has the roofing nail head feeding system on the top.

A roofing nail is mainly used for installing roofing (sometimes for water resistant drywall,tile backer board etc). The main feature that distinguishes a roofing nail is its large head,galvanization appearance, which is usually much larger and flatter than other types of nails. This permits the nail to hold down roofing felt and roofing shingles without tearing through the material. Roofing nails generally come in lengths of 1 to 1.75 inches (2.54 to 4.44 cm), although shorter and longer nails can be found.

The Process of How to Make Roofing Nails:

- Using the wire drawing machine draw steel wire to the needed diameter. The difference with the coming nail making is that this needs to add a twist device to make the steel wire spiral, the aim is to help the spiral grab the wood well.

- Second step is make the roofing nails with roofing nail making machine. This step looks simple but actually it needs skilled operation to make one shaft one head, if not, there will be some problems such as there is no head for the shaft or one nail body have 2 head. But don’t worry for this problem, you can learn the skills in your factory until you master all the skills perfectly.

- Galvanization. Because the roofing nails should bear couple of years rain, snow ,sunshine etc., so galvanization is a must to prevent the roofing nails from rusting.

Here are Some Pictures of the Application Site of Our Clients:

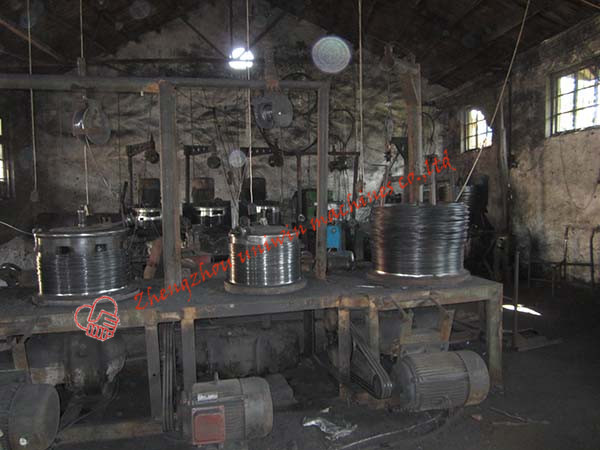

Wire Drawing Machine:

Roofing Nail Making Machine:

Galvanization of Roofing Nails Come from the Nail Making Machine:

Finished Roofing Nails Pictures:

This is our Uganda clients came and visited us for technical learning.