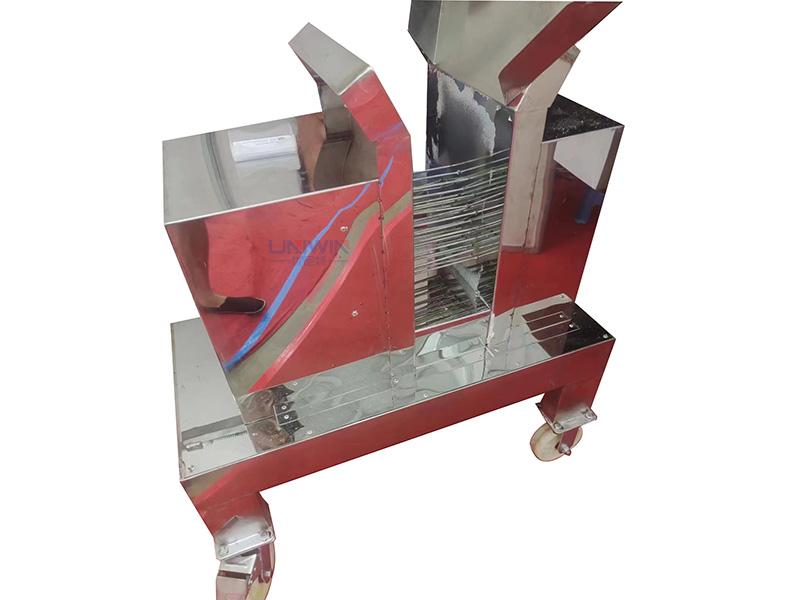

Automatic Magnetic Feeding Machine for Lifting Metal Materials

The magnetic feeding machine uses magnetic force to convey or lift metal materials. We originally designed the feeding machine to achieve an uninterrupted supply of nails between the thread rolling machine and the coil nail making machine. The Uniwin magnetic nail feeding machine can handle nails with a specification of 19-130mm (or 3/4″-5″), ensuring that nails can be continuously and stably delivered to the nail coiling machine during high-speed production, thereby greatly improving the efficiency of the coil nail production line. This automated design reduces manual intervention and optimizes the entire production process, making nail manufacturing more efficient and reliable.

However, in addition to nail production, this magnetic feeding machine can also be used in production lines for standard parts such as screws, bolts, metal washers, and other production processes that require a continuous supply of metal materials, such as metal stampings, springs, and steel needles. These industries can use magnetic feeding machines’ automation and efficient conveying characteristics to improve production efficiency and product quality.

Magnetic Nail Feeding Machine Parameters

| Electric Power | 3 Phase 380V 50Hz |

|---|---|

| Main Motor | 200W |

| Feeding Speed | 3000psc/min |

| Nail Length | 19-130mm or 3/4”-5” |

| Feeding Height | 1650-2500mm |

| Magnet Type | Ferrite Magnet Chain |

| Slide Type | Stainless Steel Slide |

| Working Area | 2100*390*2500mm |

| Machine Weight | 160kg |