Key Spare Parts for Enkotec High-Speed Nail Making Machines Available

The uniwin high-speed nail making machine is our newly designed rotary-type nail machine with obvious advantages over traditional equipment. Its unique feature is that it can be installed with a nail counter to count nail numbers accurately. The maximum production speed can reach 2000 pieces/minute, and the production capacity is equivalent to the efficiency of 8-10 ordinary nail-making machines.

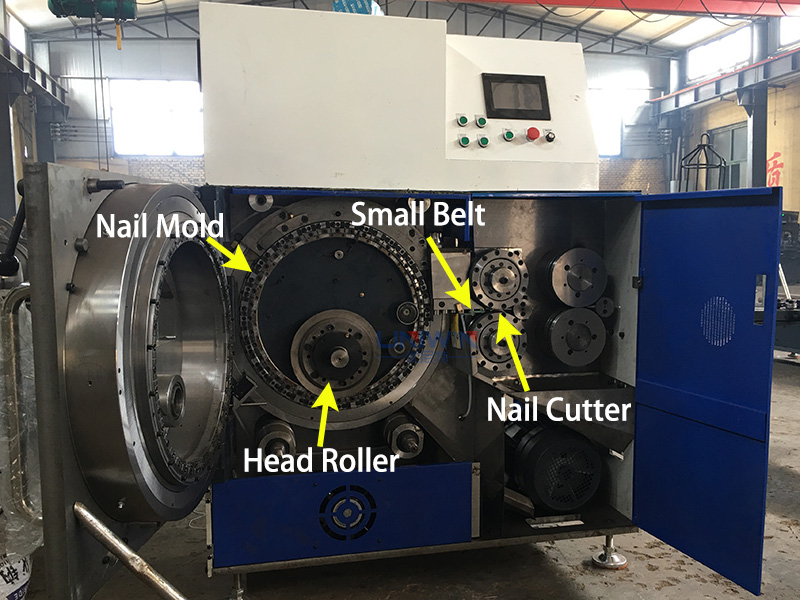

We provide a full set of spare parts for high-speed nail making machines, such as nail molds, nail cutters, head rollers, small belts, gripper pins, tension blocks, die feeders, etc., to ensure continuous efficient operation and easy maintenance of the high-speed nail equipment.

Critical Spare Parts for High-Speed Rotary-Type Nail Making Machines

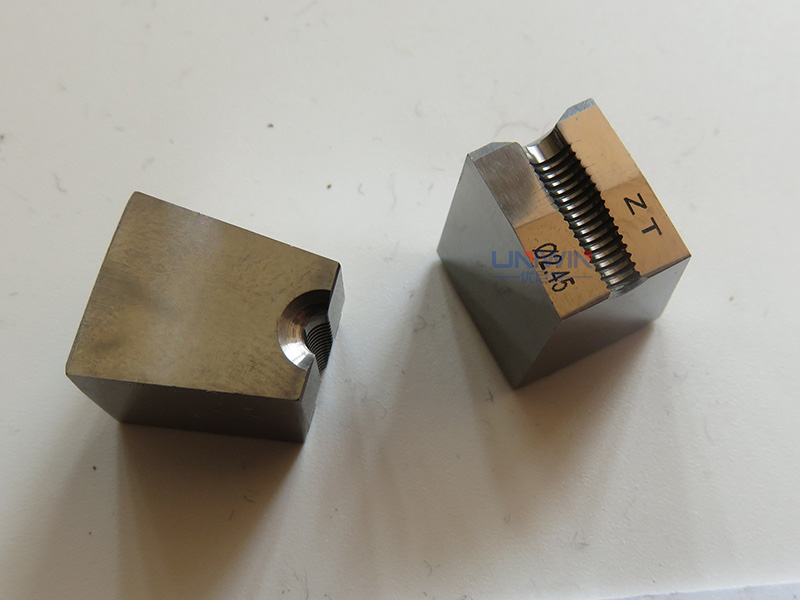

Nail Cutter: Cuts the wire to form the nail tip, with a 2-4 months service life. Excessive use will cause inaccurate cutting and affect the nail size.

Head Roller: Responsible for nail head forming. It needs to be replaced every 1-2 months. When the roller is worn, the shape of the nail head will deviate, causing the nail not to meet the specifications.

Nail Mold: Grip the wire to form the nail head at the head roller, usually with a long life of 2-3 years.

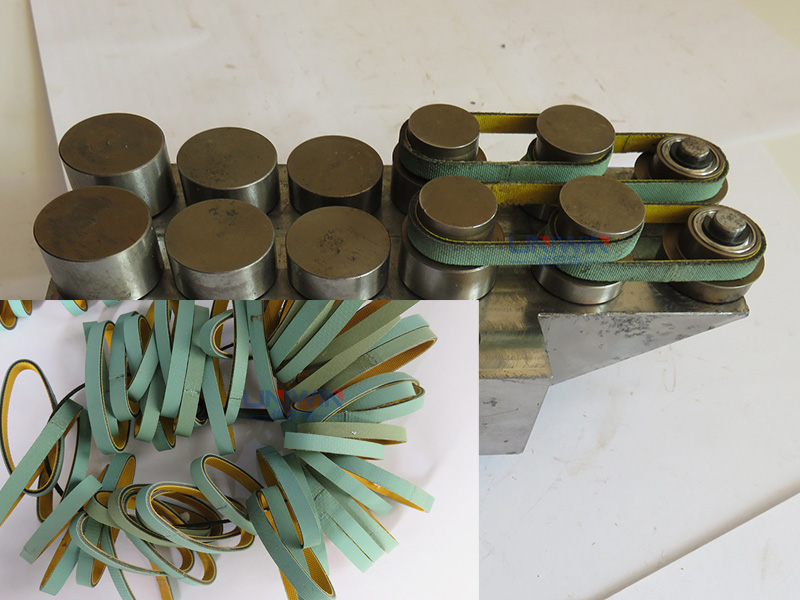

Small Belt: Used for die feeder, accurately feeds the wire to the nail mold position to complete the final nail head forming, usually replaced every 2-3 days.

Regular lubrication, cleaning and inspection of key components effectively extend their service life. For parts that are easy to wear, such as nail cutters and small belts, it is recommended to keep a certain inventory to avoid nail production downtime.