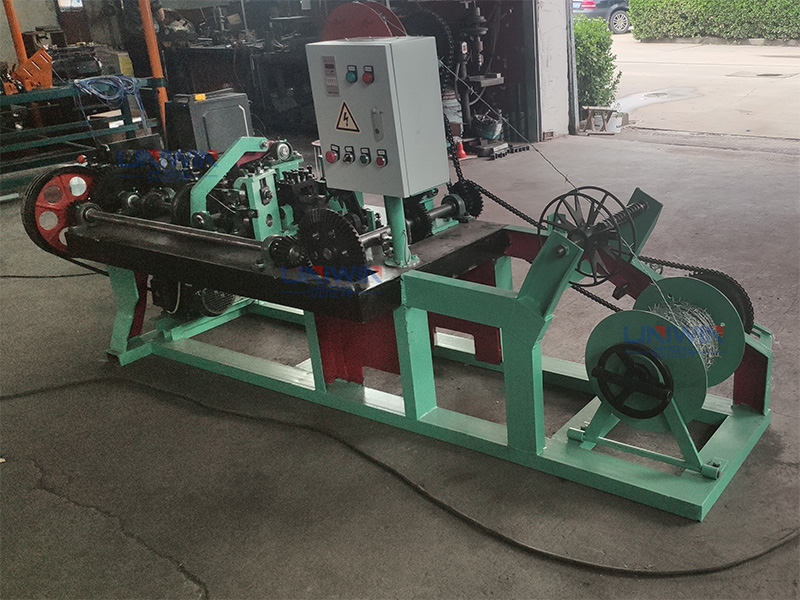

What is J Series Staple Making Machine?

The J series staple making machine is a technologically advanced system for producing 10J/4J/80/71/84/93/ Series staple pins with safety operation and low noise. This machine incorporates a hydraulic system rather than traditional heavy punching, which leads to a smoother and more efficient operation with less waste. It’s controlled by a PLC system, ensuring precise and stable performance.

Staple pin making machine working video

Small staple J series staple making machine parameter

| No. | Item | Specification |

|---|---|---|

| 1 | Model | XM-J30 Staple Machine |

| 2 | Motor Power | 5.5kw |

| 3 | Operating Voltage | 380/50Hz |

| 4 | Number of Stroke | 100-170times/min |

| 5 | Daily Output (8 Hours) | 600-1000kg |

| 6 | Wire Band Width | 80-150mm |

| 7 | Wire Band Thickness | 0.4-1.2mm |

| 8 | Nail Type Available | 10J/4J/8071/84/93/ Series, etc. |

| 9 | Feed/Push Method | Pneumatic |

| 10 | Machine Size | 1400*1100*1750mm |

| 11 | Machine Weight | 1430kg |

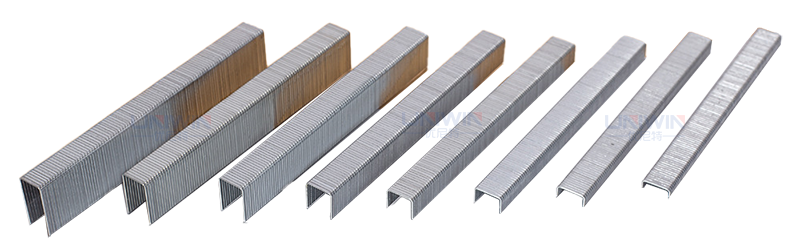

Finished small staple pins

The raw material of staples is galvanized wire. J series staples are commonly used in furniture, upholstery, and other industries.

Staple pin production line

The basic production process of staple nails is:

First, the galvanized wire is pressed by the wire flattening machine, then glued by a multi wire gluing machine, and finally formed by a staple making machine.

Or you can directly purchase wire bands and a staple pin making machine to produce staple pins.

J staple making machine price

The J staple making machine price is USD 5000-8000.