What is copper coated coil nail welding wire?

The copper coated coil nail welding wire refers to a welding wire coated with a layer of copper for welding nails into coil nails through the coil nail making machine. Welding wire for coil nails is mainly used to produce various coil nails. The wire is made of low-carbon steel wire that undergoes heat treatment, ensuring its durability and strength. And the copper layer enhances its welding capabilities and provides strong oxidation resistance. When using it to weld coil nails, there is a stronger bond between the nails and the copper plated welding wire, and the weld is not easily broken. And the nails and the welding wire can be easily detached when using a nail gun.

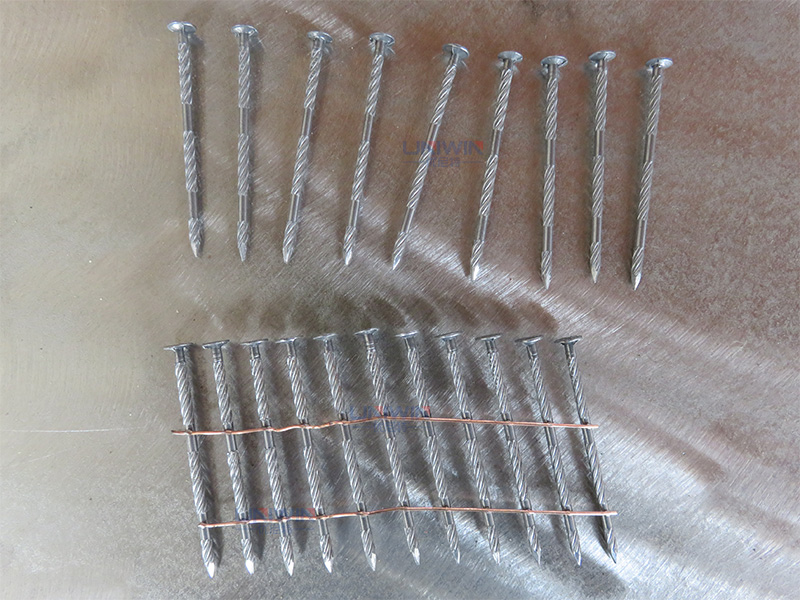

Copper Coated Welding Wire For Coil Nails

| No. | Item | Specification |

|---|---|---|

| 1 | Brand | Uniwin |

| 2 | Material | Low Carbon Steel Wire |

| 3 | Surface Treatment | Copper Plating |

| 4 | Diameter | 0.6-0.8mm |

| 5 | Packing | 25kg/Spool |

Choose the right welding wire diameter for your nails

The copper coated coil nail welding wire has various diameters, including 0.6mm, 0.7mm, and 0.8mm. The choice of diameter is contingent on the length of the nail. For instance,

Nail length shorter than 50mm would use a 0.6mm welding wire.

Nails between 50-80mm would require a 0.7mm welding wire.

In terms of usage, approximately 20kg of this copper coated welding wire is used for every ton of coil nails.

Features of copper coated coil nail welding wire

- Good anti-corrosion and anti-rust performance. Because the main component of welding wire is steel, bare wires are prone to rust and corrosion in the atmosphere. A layer of copper coating on the surface can effectively extend the shelf life. It can resist rust and corrosion for 12 months without opening the box in humid weather.

- Copper plating makes the surface of the welding wire smoother, increases wire feeding speed, and enhances conductive properties.

- Strong adhesion. The copper layer is closely combined with the steel wire to maintain stability and reliability during welding.

- Wide application range. This welding wire can weld different nails, such as smooth shank nails, ring shank nails, screw shank nails, etc.

Factory show