Collated Gas pin nail assembly machine for producing gas nails used with gas-powered nail guns

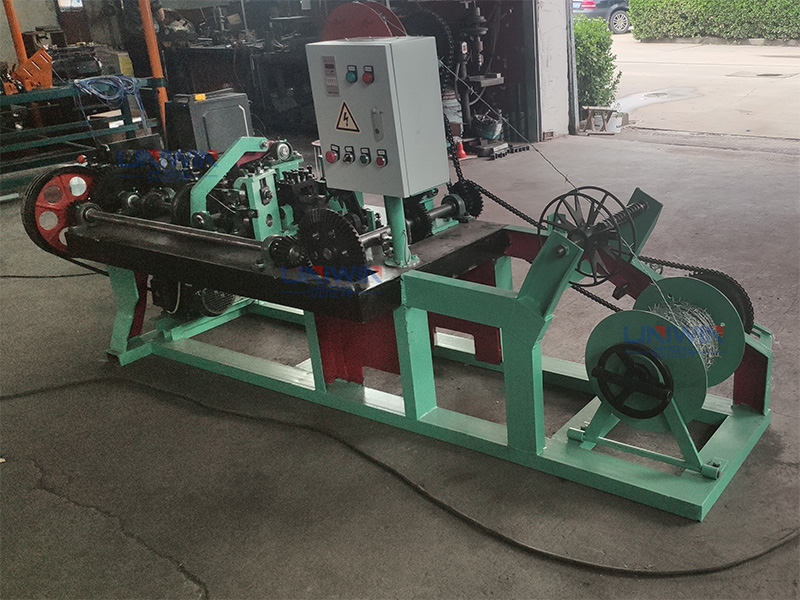

The collated gas pin nail assembly machine is a highly automated system designed to produce gas nails continuously at a high speed of 50 strips per minute. The equipment is equipped with two vibrating feeding trays and various sensors, such as shutting down for lack of material, reminding for low material, shutting down for long material, etc., to ensure the correct position and stable supply of nails and plastic strips.

Gas nails are usually made of high-strength 55# steel and used with a gas nail gun, allowing many fastening operations to be quickly performed in the construction and manufacturing industries, significantly improving work efficiency and reliability. Gas nails are commonly used to install steel plate building materials on cement floors and walls.

Parameter of High Speed Gas Nail Assembly Machine

| No. | Item | Specification |

|---|---|---|

| 1 | Model | ZS-4 |

| 2 | Working Power | 0.75kw |

| 3 | Voltage | 220V 50Hz |

| 4 | Nail Length | 19-40mm |

| 5 | Working Speed | 50pcs/min |

| 6 | Machine Size | 1300*1400*1400mm |

| 7 | Machine Weight | 480kg |

Choose the appropriate gas nail length according to the corresponding nailing material:

Like:

Nail the concrete floor or wall, choosing within 25mm

Shooting wood, optional 32/35mm

The gas nail gun can install nail size: 19-40mm

Features and Advantages of Plastic Strip Gas Pin Nail Collated Machine

- Material Shortage Shutdown Sensor: This ensures that the machine will automatically stop when the nails and plastic strips are used up to prevent empty hitting and damage to the collated gas pin nail assembly machine.

- Low Material Supply Sensor: It monitors the supply of nails and plastic strips to ensure advance notification when they are about to be used up so that they can be replenished in time and reduce downtime.

- Long Material Shutdown Sensor: If the nails exceed the set length, the sensor will detect and stop the machine to ensure product quality.

- Nail Vibrating Plate and Plastic Strip Vibrating Plate: it automatically sorts and transports nails and plastic strips to the assembly area to ensure continuous feeding.

- Push Brushes: These brushes are used to guide plastic strips during assembly, ensuring their accurate position and stable supply.

- Nail Insertion Plate: It is used to guide nails into the plastic row during manufacturing correctly and is crucial to ensure the quality of gas nail assembly.

- Nail Stuck Sensor: If a nail is stuck or not assembled correctly, the sensor will detect and stop the machine to prevent damage to the collated gas pin nail assembly machine and defective products.