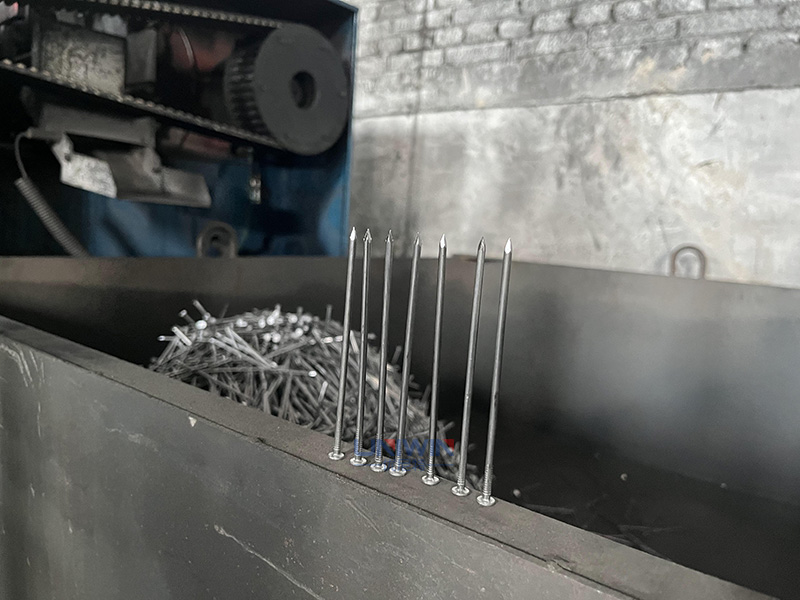

Cold Drawn Steel Wire for Nail Manufacturing

Cold drawn steel wire is a critical raw material in the nail manufacturing process. Cold-drawn wire is usually made by drawing a steel wire rod with a 6.5 mm or 5.5 mm diameter through a wire drawing machine multiple times until it reaches the specification required for nail production. The common cold-drawn steel wire diameter ranges from 1.2 mm to 5.0 mm, suitable for different nail production lines. During the cold drawing process, the steel wire’s strength, hardness, and surface finish are improved, and it is highly suited for high speed nail making machines.

Cold Drawn Steel Wire Size Specifications and Types

We provide a variety of specifications and types of cold drawn steel wire to meet the needs of different nail production. Common diameter ranges of cold-drawn steel wire used in nail making machine factories are:

Wire Diameter Range: 1.2 mm, 2.0 mm, 2.2 mm, 2.5 mm, 2.8 mm, 3.1 mm, 3.4 mm, 3.7 mm, 4.1 mm, 4.5 mm, 4.7 mm, 5.0 mm

Weight per Coil: about 350 kg

Cold-Drawn Steel Wire Types: Low Carbon Steel Wire (Q195, Q235), Medium and High Carbon Steel Wire (#45, #65), Alloy Steel Wire (C1022)…

These cold drawn steel wire specifications and materials provide flexible options for nail production, ensuring high performance and durability in different application scenarios.

Uniwin Cold Drawn Steel Wire

Uniwin’s cold drawn steel wire greatly improves production efficiency and finished nail quality with its high strength, a wide range of specifications, and high-quality surface treatment. Using Uniwin’s cold drawn steel wire in a nail making machine factory can help improve overall nail production quality and consistency. Whether common wire nails, coil nails, concrete nails, or self-tapping screws, Uniwin’s cold-drawn wire can provide a solid material guarantee for all kinds of nails.