Nail Making Wire Guide | Buy MS Wire for Nails from Uniwin

In nail production, the most critical step is to choose the right raw materials – nail making wire. Whether the nails are well made, whether the nail equipment runs stably, and whether the production capacity is high are closely related to the iron wire you use.

Many customers will ask us when they are preparing to produce nails for the first time:

What is the raw material for making nails?

What kind of wire for nail making should I buy and how to choose the thickness?

Can nails be made without a wire drawing machine?

What else can you provide besides iron wire?

……

We Uniwin summarize these questions for our customers. The following article will help you explain the types of nail making wire, selection methods, usage recommendations, and supporting equipment at once!

What Materials are Nails Made of?

The primary material for making nails is low-carbon steel wire, commonly referred to as MS wire for nails in the nail industry.

You’ll generally find two types of raw wire on the market:

Wire Rod (6.5mm / 5.5mm)

Original thick steel wire, often Q195 or Q235

Each coil weighs around 2 tons

Requires a wire drawing machine to reduce it to the desired diameter

Drawn Nail Wire

Already drawn to a specific diameter

Ready to use with nail making machines

Ideal for beginners or customers without wire drawing equipment

What is Nail Making Wire?

Nail making wire is steel wire that’s been drawn, annealed, etc. and is ready for nail manufacturing equipment.

- Clean Surface, No Rust

- Consistent Diameter

- Works Great With High-Speed Nail Machines

- High Production, Low Waste

Uniwin supplies nail making wire in various diameters, including:

1.2 / 2.0 / 2.2 / 2.5 / 2.8 / 3.1 / 3.4 / 3.7 / 4.1 / 4.5 / 4.7 / 5.0 mm

Not sure what diameter you need? No problem! Tell us what kind of nails you want to make, and we’ll recommend the best option.

Which Type of Wire is Suitable for the Nails You Make?

Different nails need different wire materials. Here’s a quick guide to help you decide:

| Wire Type | Features | Common Use |

|---|---|---|

| Black Annealed Wire | Soft And Easy To Process | Common Wire Nails/Decoration Nails |

| Electro-Galvanized Wire | Bright Surface, Rust-Proof | Furniture Nails/Decorative Nails |

| Hot-Dip Galvanized Wire | Thick Galvanized Layer, Strong Corrosion Resistance | Coil Nails/Roofing Nails/Outdoor Nails |

| Medium/High Carbon Steel Wire (45#/65#/C1022) | High Hardness, Strong Tensile Strength | Concrete Nails/Self-Tapping Nails |

Can You Make Nails Without Wire Drawing Machine?

Of course! Many customers did not have wire drawing equipment when they started making nails. They start production directly with finished nail making wire.

You can choose based on your current setup:

No Wire Drawing Machine:

Buy finished nail making wire from Uniwin or the local market

Use it directly with nail machines

No need for too much equipment, and save costs

With or Planning Drawing Line:

Buy 6.5mm wire rods from Uniwin or the local market

Use wire drawing machines to draw wire into different diameter

Lower cost, more flexible processing

If you plan to draw wire yourself later, we can also provide wire drawing equipment for you, including:

Wire Drawing Machine

Automatic Wire Take-Up Machine

Wire Pay-Off Stand

Annealing Furnace

Galvanizing Equipment and Accessories

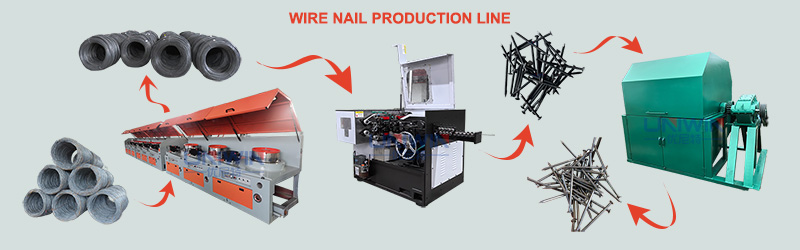

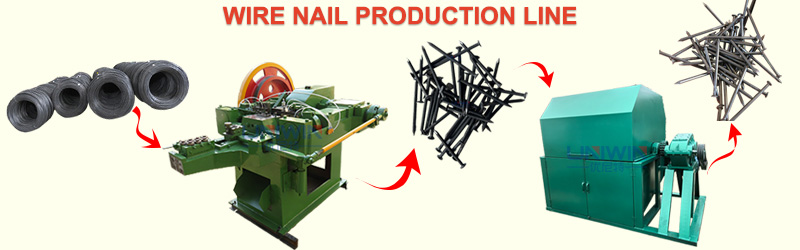

The Nail Production Process:

Option 1:

Wire Rod → Wire Drawing → Nail Making → Polishing → Packaging

Option 2:

Nail Making Wire →Nail Making → Polishing → Packaging

For new factories, we recommend starting with option 2. It’s faster to set up, has a quicker payback period, and requires less equipment investment.

Get in touch with us, and we’ll help you to choose for nail production!