Collated Screw Assembly Machine Introduction:

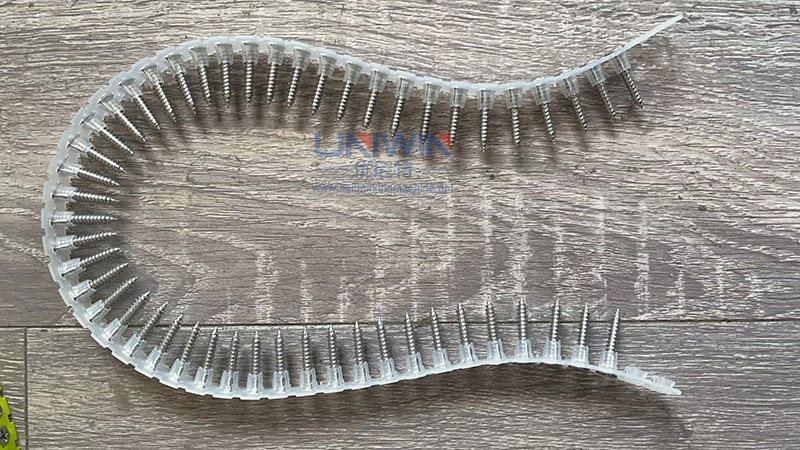

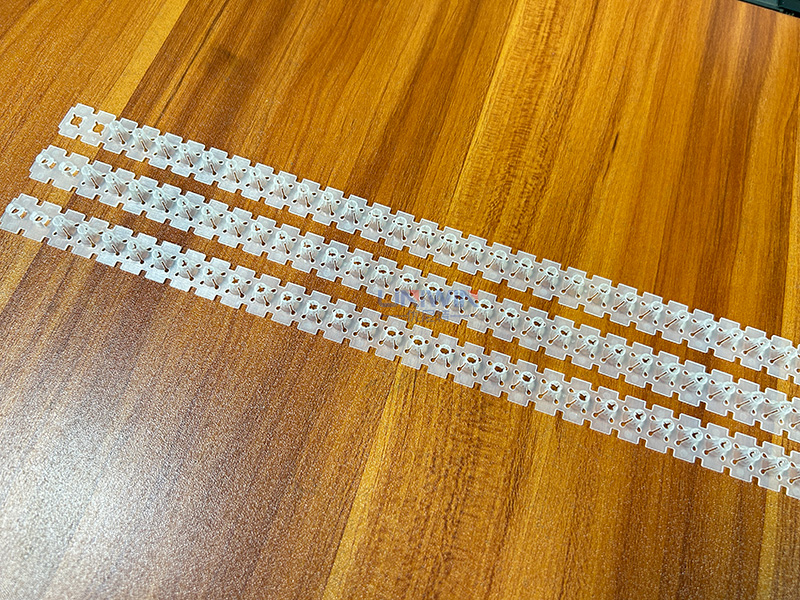

The Collated Screw Assembly Machine is designed to assemble drywall screws into plastic belts with speed 600-1200 pieces per minute, streamlining the process of fastening drywall screws and other materials. There are 50 screws assembled per belt, with 2 holes for connecting each belt on the two sides.

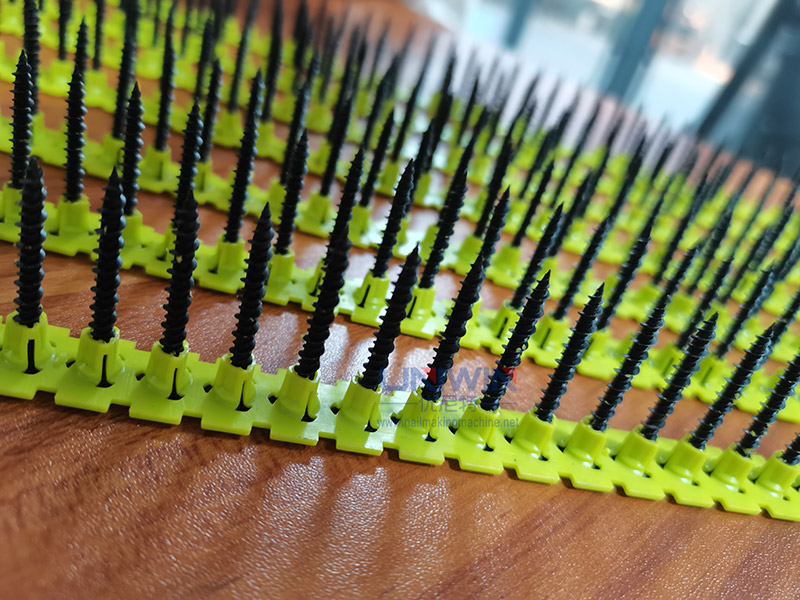

There are two types of strips to be used for screw nails assembling, ie injection molded type strip and the punched type strip. Nowadays the injection type are becoming more and more popular.

Parameters of the Collated Screw Assembly Machine:

| Model | NCS-CYDX |

|---|---|

| Diemension (LxWxH) | 3248x1135x1720 mm |

| Voltage | 220V Single phase 220V |

| Frequency | 50/60Hz (optional) |

| Power | 5.5KW |

| Working speed | Up to 800-1250 pcs/min (adjustable) |

| Assembly range | Diameter 3.5mm, Length 25-55mm |

| Air pressure | 1.0Mpa |

Capacity: The Collated Screw Assembly Machine can process a large number of screws per minute, significantly reducing the time required for assembling screws manually.

Screw Size: This versatile machine is designed to accommodate various screw sizes, making it suitable for a wide range of applications.

Collation Materials: The machine is compatible with different types of collation materials, such as plastic belts and wire coils, offering flexibility in choosing the most appropriate material for specific needs.

Power Source: The machine operates on electricity, ensuring consistent performance and reducing the dependency on manual labor.

Dimensions: The compact design of the Collated Screw Assembly Machine makes it easy to integrate into existing production lines without occupying much space.

Collated screw assembly machine advantages:

PLC Control: Fully automatic, can collate max 1250 pcs drywall screws per minute.

Increased productivity: The Collated screw assembly machine significantly reduces the time and effort required for assembling screws, resulting in increased productivity and overall efficiency.

Consistent quality: The machine ensures consistent assembly and collation of screws, eliminating the possibility of human error and improving the overall quality of the final product.

Enhanced safety: By automating the screw assembly process, the Collated screw assembly machine minimizes the risk of workplace injuries associated with manual handling of sharp objects.

Cost-effective: This advanced machine reduces labor costs and improves production rates, making it a cost-effective solution for businesses in the long run.

Easy integration: The collated screw assembling machine can be easily integrated into existing production lines, making it a seamless addition to manufacturing facilities.

Different uses of collated drywall screws:

Collated drywall screws: Used for connecting gypsum boards, light steel or wooden studs;

Collated chipboard screw: Used for assembling furniture;

Collated self-drilling screws: Used for installing metal sheets and constructing metal frames;

Collated decking screws: Used for securing outdoor flooring.