Advanced Rubber Banding Solution for JD-100 Coil Nail Machines

The automatic rubber banding system is designed for the JD-100 nail coiling machine, ensuring compatibility without changing the original circuit system. This rubber banding system supports nail lengths of 25-100mm, coil diameters up to 136mm, and speeds of 12 coils/min. It integrates multi-functional capabilities, including automatic counting, cutting, nail coiling, rubber band application, and finished coil nail delivery. Equipped with an independent control cabinet featuring a PLC and touch screen, it supports parameter adjustments, fault detection, and WiFi connectivity, significantly enhancing the machine’s intelligence and production efficiency.

Technical Specifications of Automatic Rubber Banding System for Coil Nail Production

| Model | Automatic Rubber Banding System for Coil Nail Machine |

|---|---|

| Nail Length Range | 25-100mm |

| Coil Nail Maximum Diameter | 136mm |

| Maximum Speed | 12 coils/minute |

| Rubber Band Diameter Range | 32-50mm |

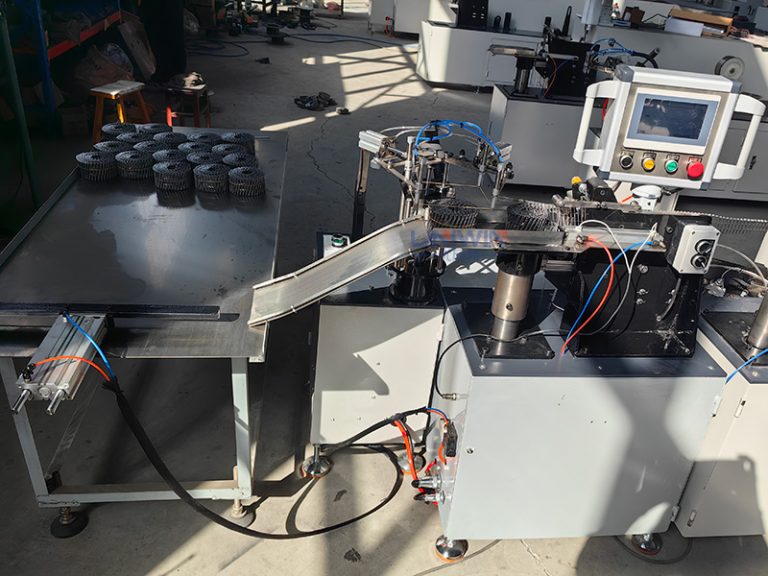

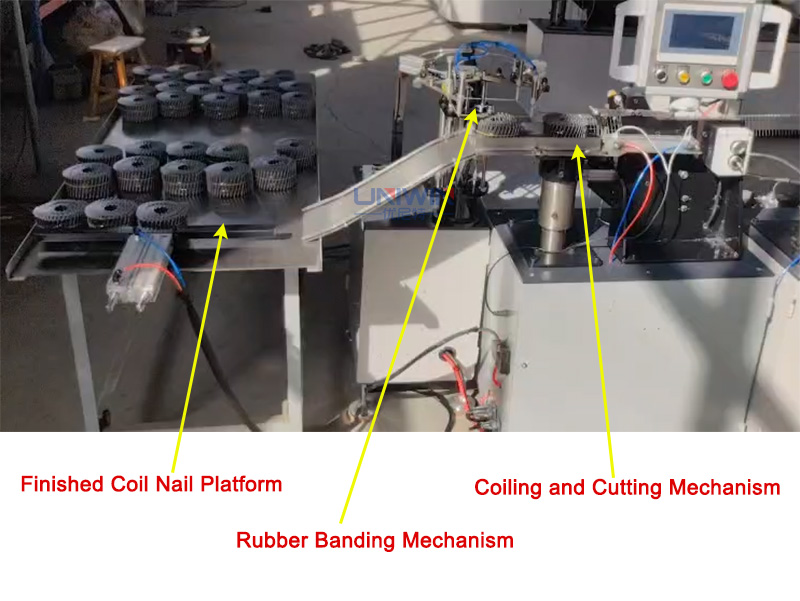

Equipment List: Coiling and Cutting Mechanism, Rubber Banding Mechanism, Finished Coil Nail Platform, Buffer, etc.

Features and Advantages of Automatic Rubber Banding System for Coil Nail Machine

- Fully Automatic Operation

Automatically complete the coil nail forming and rubber banding, and delivery to the finished product platform, reducing the labor intensity and avoiding the deformation of finished coil nails caused by manual operation errors. - Upgraded Finished Product Platform

The platform capacity has been increased and can store about 60 coil nails, supporting the adjustment of the inner and outer of the finished product output directions. - Patented Cutting Technology

The uncutting probability is reduced to 1/10 of that of ordinary models, ensuring minimal waste and consistent operation. - Intelligent Protection Function

Includes welding wire exhaustion and burnout protection, uncut product alerts, rubber band exhaustion alarms, etc., and the fault location can be accurately displayed on the touch screen. - Improve the Quality of Finished Products

The nail cap is flat and beautiful, the coil nails are moderately tight, and the tension parameters can be directly adjusted through the touch screen to ensure that each coil nail is uniform and consistent. - Intelligent Control System

Equipped with a Huichuan PLC and WiFi network touchscreen interface, it supports parameter adjustment and automatic fault stop display. - Production Process Optimization

The distance from painting to cutting is extended from 1 meter to 2.5 meters.