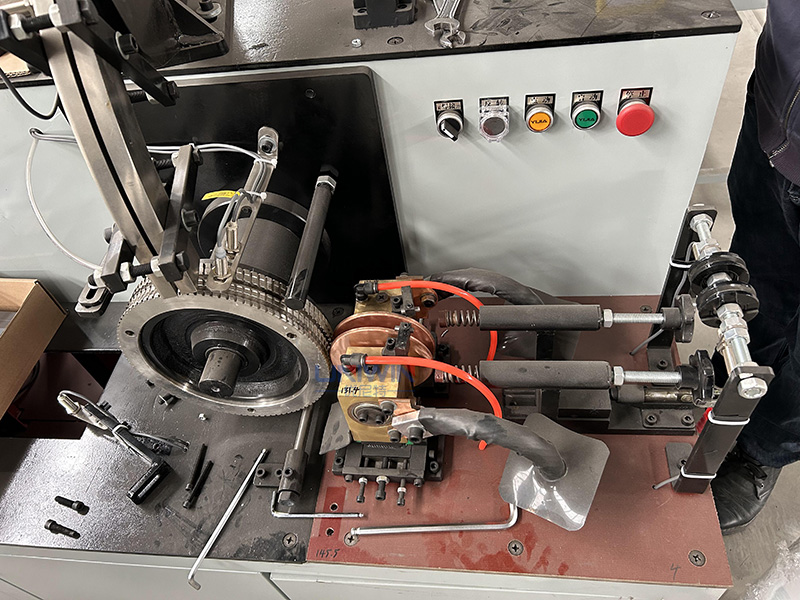

Coil Nail Making Machine Welding Adjustment Guide

- Welding Current: It can be obtained by adjusting the welding power supply. After adjustment, the output current is constant. The larger the current, the larger the spark, the larger the welding point, and the hotter the nail.

- Welding Wheel Pressure: The larger the pressure, the smaller the welding spark; vice versa. If the spark is large on one side and small on the other side, you can adjust the pressure on both sides to balance the spark. If the welding points on both sides are too small simultaneously, try to reduce the pressure or increase the current simultaneously and vice versa.

- Welding Wheel Height: It is based on the two welding wheels pressing on a nail at the same time.

- Welding Timing: The main phenomenon of improper timing is that the welding point is black and red. The welding timing can be obtained by adjusting the counting wheel rotation angle, and the adjustment range is a fraction of the teeth space of the counting wheel.

Common Problems and Solutions for Coil Nail Welding

| Phenomena | Solutions |

|---|---|

| Faulty Solder on One Side of Nails | Reduce The Welding Wheel Pressure on The Faulty Solder Side/Increase The Pressure on The Side That Is Not Faulty Soldered |

| Faulty Solder on Both Sides of Nails | Increase The Welding Output Current/Reduce The Pressure at The Same Time |

| Too Large Spark | Increase Pressure at The Same Time/Reduce Welding Current |

| Welding Wire Easy to Break (The Welding Wheel Is Old and Damaged/The Welding Wire or Nails Are Rusted) | Adjust The Welding Pressure/Reduce The Current |

| Too Hot Nails | Reduce Welding Output Current/Ensure Normal Operation of Water Cooling |

Note: It is strictly forbidden to use rusty nails or rusty welding wires when working on the machine.