What is nail polishing machine?

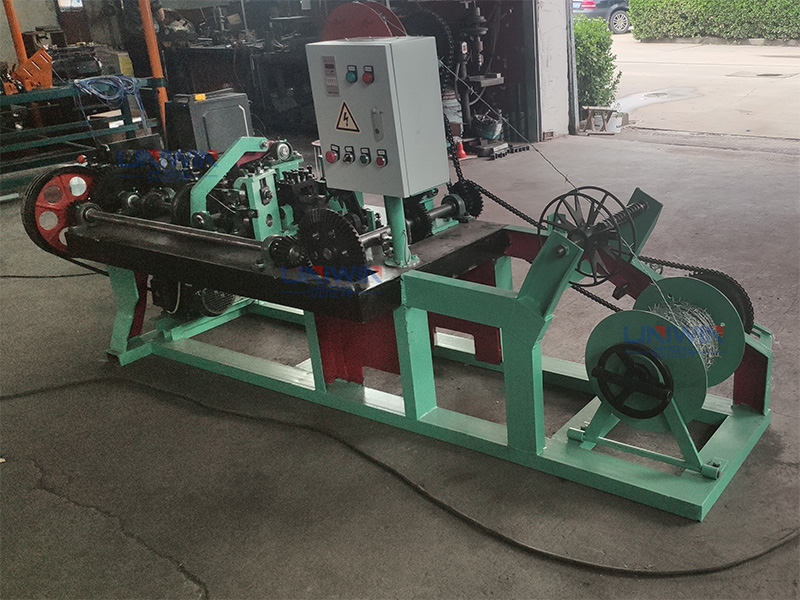

The nail polishing machine in the nail production line is used to polish and finish metal nails and hardware components after manufacturing. The working principle is based on the abrasive action resulting from the tumbling of nails with polishing media, such as sawdust, paraffin, and waste engine oil. After nails are produced, they often have rough edges, burrs, or surface imperfections. The machine addresses these issues by providing a smooth and shiny finish to the nails, making them ready for packaging and sale.

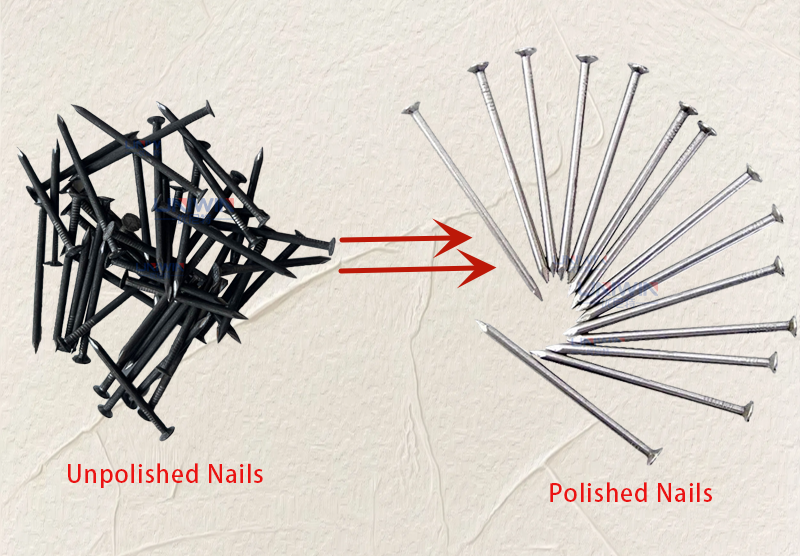

Nail Polishing is the last step for making wire nails. Before polishing, the nails come out from the wire nail making machine in black color. After polishing, the nails will get bright and rush-proof.

Specification of nail polishing machine

| Model | Motor Power | Capacity | Size |

|---|---|---|---|

| SD-400 | 3kw | 400kg/time | 1650*900*1000 |

| SD-600 | 4.5kw | 600kg/time | 1950*1000*1100 |

| SD-1000 | 7kw | 1000kg/time | 2000*1500*1400 |

Features of nail polishing machine

The nail polishing machine has several features designed to enhance its efficiency, safety, and the quality of the polished nails. Here are the key features of the machine:

- Rotating Drum or Barrel: It holds nails and polishes media. The drum’s rotation facilitates the tumbling action necessary for the polishing process. When the machine is turned on, the nails tumble inside the drum, and the abrasive action of sawdust smoothens and cleans the nails.

- Polishing Media: The polishing media is added to the drum to polish nails, such as sawdust, paraffin, and waste machine oil. Saw dust removes any sharp edges, engine oil is used to brighten nails and give a shiny surface, and paraffin increases the rust resistance of nails.

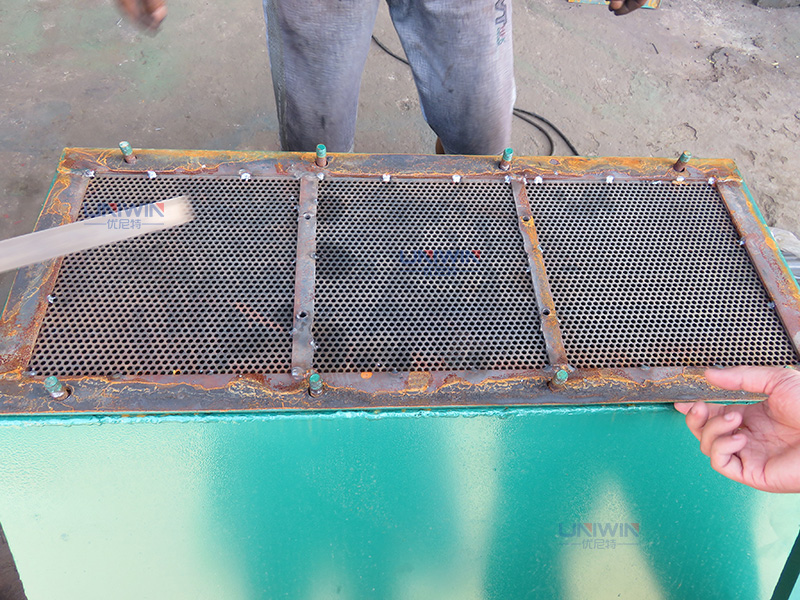

- Cover with mesh: Each polisher is equipped with two different lids. After polishing, the cover with mesh replaces the original one to separate the polished nails from sawdust, paraffin and waste oil.

- Dust Collection System: The machine has a dust collection system that captures the dust and debris generated during polishing, maintaining a clean working environment.

- Automatic Operation: Modern machines are automated, allowing continuous operation without constant manual intervention. This feature enhances production rates and ensures uniform polishing.

Nail polishing machine application

The primary application of the nail polishing machine is in the nail manufacturing industry, where it plays a crucial role in enhancing the quality and appearance of metal nails. Polished nails have a better aesthetic appeal, are free from imperfections, and are less likely to cause issues during their application.

Nail polishing machine price

The nail polishing machine price is USD 1000-2500. They are available in different drum sizes and capacities depending on production volumes. Customized machines can also be built as per specific needs.