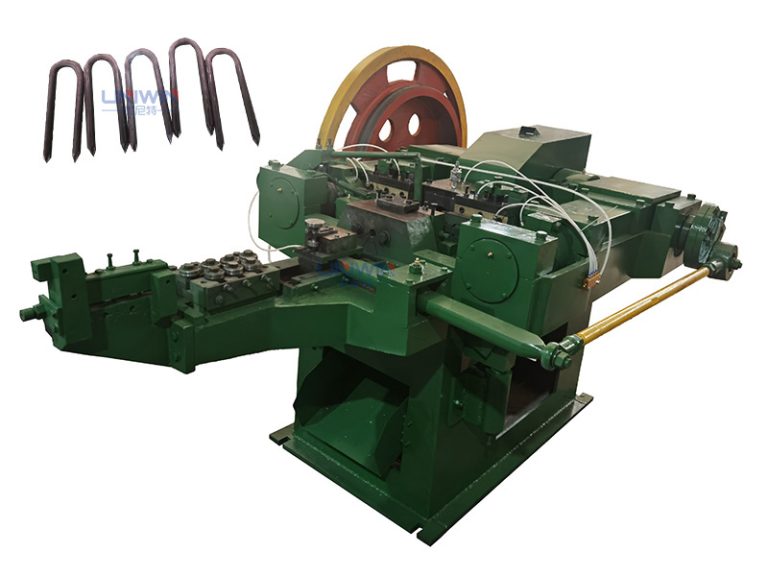

What is U shaped nail making machine?

The U shaped nail making machine is designed to automatically produce u shaped nails of different sizes and shapes, depending on the specific application’s requirements. The advantages of using a U-shaped nail making machine include increased production speed, consistent nail quality, and reduced labor requirements compared to making nails by hand. This machine is commonly used for fixing metal plate nets, wire meshes, wire fences, barbed wires, and other construction and woodworking applications.

What are U shaped nails?

U shaped nails, also known as staple nails or U nails, have smooth and barbed shanks. They can be made from various materials such as cold drawn wire, galvanized wire, galvanized steel wire, or stainless steel wire. You can choose one type depending on specific applications and requirements. They are often used to secure mesh fencings or barbed wires to wooden posts, such as in fencing or upholstery. U shape nails can also be used to fasten wires in place and fix turf on golf courses, garden lawns, and other places where turf is needed.

Working principle of U nail making machine

The working principle of a U nail making machine is based on the same principles as a wire nail making machine. It involves several steps to transform steel wire into U-shaped nails. Here is a detailed explanation of the working principle:

- Wire Feeding: The machine is equipped with a wire feeding mechanism that feeds the steel wire into the machine for further processing.

- Wire Straightening: The wire passes through a straightening mechanism to ensure it is properly aligned and straight before entering the nail forming process.

- Nail Forming: The straightened wire is then guided into a specialized nail mold that is designed to shape the wire into U nails. The mold grips the wire and forms the desired U shape.

- Nail Cutting: Once the U shaped nail is formed, a cutting mechanism cuts the nail to the desired length. The cutting process ensures that each nail is uniform in size.

- Nail Ejection: After cutting, the U nails are ejected from the machine and collected in a designated area for further processing or packaging.

U nail making machine parameter

| No. | Item | Specification |

|---|---|---|

| 1 | Brand | Uniwin |

| 2 | Motor Power | 4kw |

| 3 | Nail Diameter | 2.0-4.5mm |

| 4 | Nail Length | 20-100mm |

| 5 | Production Speed | 240psc/min |

| 6 | Machine Size | 2350*1500*1450 |

| 7 | Machine Weight | 2T |

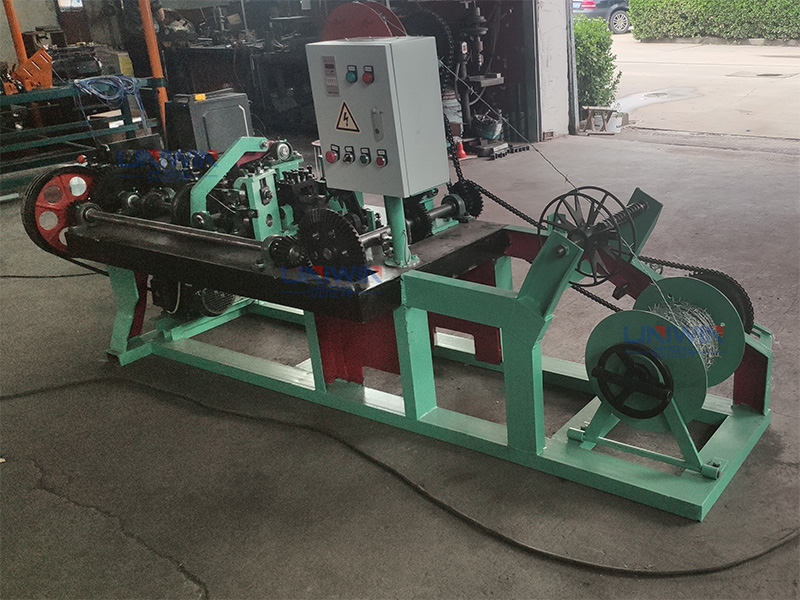

Features of U shape nail manufacturing machine

Here are some common features that can be found in U shaped nail manufacturing machines:

- High Efficiency: U-shaped nail making machines can operate at high speeds to produce U-shaped staples efficiently.

- Automatic Operation: These machines are fully automatic, reducing the need for manual intervention and increasing productivity.

- Adjustable Nail Size: The machine can often be adjusted to produce U-shaped nails of different lengths and widths, allowing for greater flexibility in production.

- Durable Construction: These machines are designed with robust materials for long-term use in industrial environments.

- Low Noise and Vibration: U nail manufacturing machines operate with minimal noise and vibration, providing a comfortable working environment.

- Easy Maintenance: The machine parts are often designed to be easily accessible for regular maintenance and cleaning.

Spare parts of U fencing nail making machine

Application of u shape nails

U shaped nails are used in applications that need to be securely fastened without piercing through the surface, such as in cable management, fencing, and upholstery. They can be used to secure cardboard boxes, crates, or pallets, fasten insulation materials, affix carpeting or underlay, and even in various crafting projects where a secure and inconspicuous fastening is required.

U shaped nail making machine price

U shaped nail making machine price is USD 5000-7000. The machine price can be different from your detailed requirements. You can contact us by sending an inquiry for your certain quotation.