Spot welding machine for broken coil nails

The spot welding machine for welding broken coil nails is a specialized tool used in the nail manufacturing industries. When a nail coil is broken, the spot welding machine can weld the break welding wire together again. This is typically done by placing the broken ends of the welding wire on the electrodes of the machine and applying a current to heat and fuse the metal. This process effectively welds the broken coil nails and reduces waste.

The spot welding machine is a type of welding equipment used to join two metal surfaces together by applying heat through an electric current without damaging the internal structure of the workpiece to be welded. The machine adopts a foot-operated pressurizing mechanism. It is often used in the manufacturing industry for various applications, including welding broken coil nails.

Resistance spot welder machine parameter

| Model | Rated Capacity | Primary Voltage | Duty Cycle | Welding Thickness |

|---|---|---|---|---|

| DN-10 | 10KVA | 380V | 20% | ≤1.5+1.5mm |

| DN-16 | 16KVA | 380V | 20% | ≤2+2mm |

| DN-25 | 25KVA | 380V | 20% | ≤3+3mm |

| DN-35 | 35KVA | 380V | 20% | ≤3.5+3.5mm |

| DN-40 | 40KVA | 380V | 20% | ≤4+4mm |

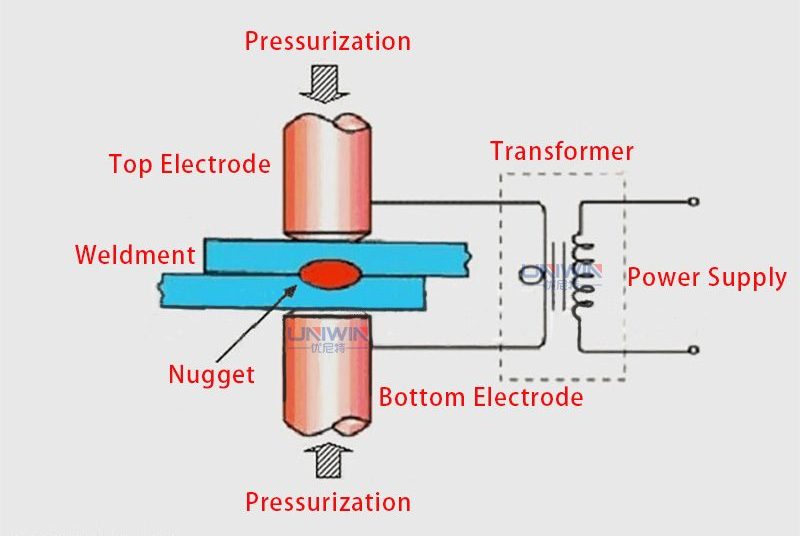

Automatic spot welding machine working principle

The spot welding machine for welding broken coil nails operate based on the same principles as general spot welding. However, specific parameters such as spot welding temperature, current, voltage, and process may vary depending on the specific requirements of coil nails.

Spot welding temperature

The temperature required for spot welding can vary depending on the type of welding wire metal in the coil nail, but it’s typically 870 to 1400 degrees Celsius. The goal is to reach a temperature that melts the surfaces of the welding wire ends without burning through.

Spot welding current and voltage

The current in spot welding is typically high, ranging from a few thousand to tens of thousands of amperes. This high current is necessary to generate enough heat through resistance to melt the coil nail broken ends.

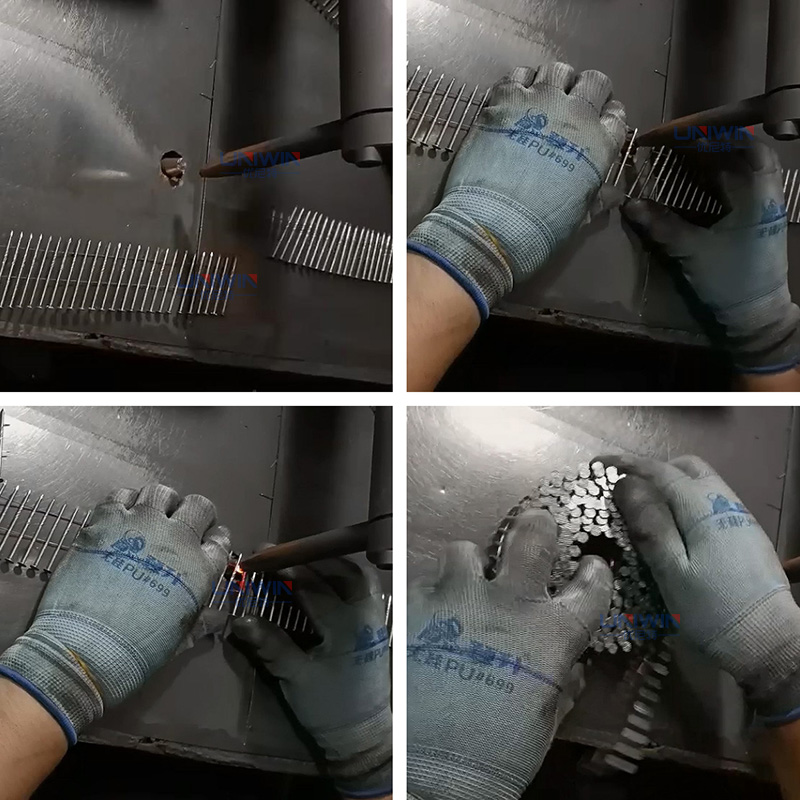

Spot welding process

- Clean the broken ends of the coil nail to ensure a good electrical connection and reduce resistance.

- Place the broken coil nail in the spot welder machine, ensuring the broken ends are correctly aligned.

- Apply pressure and electric current to the weld area. The current reacts with the metal’s internal resistance, generating heat and melting the metal surfaces.

- Maintain the pressure after the power is turned off to form a solder joint. Once the metals have cooled down, the spot welding process is complete.

Spot welding machine application

In addition to welding broken coil nails, the spot welder machine is also widely used in other manufacturing industries, such as wire mesh and fences, metal furniture, automotive parts, and medical devices.

Spot welding machine price for sale

The spot welding machine price is USD 500-1000, lower than that at Alibaba.

Spot welding machine price in Pakistan

PKR 139,750-279,500