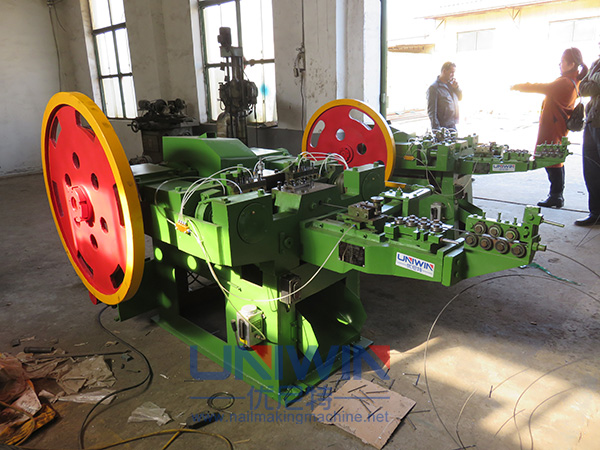

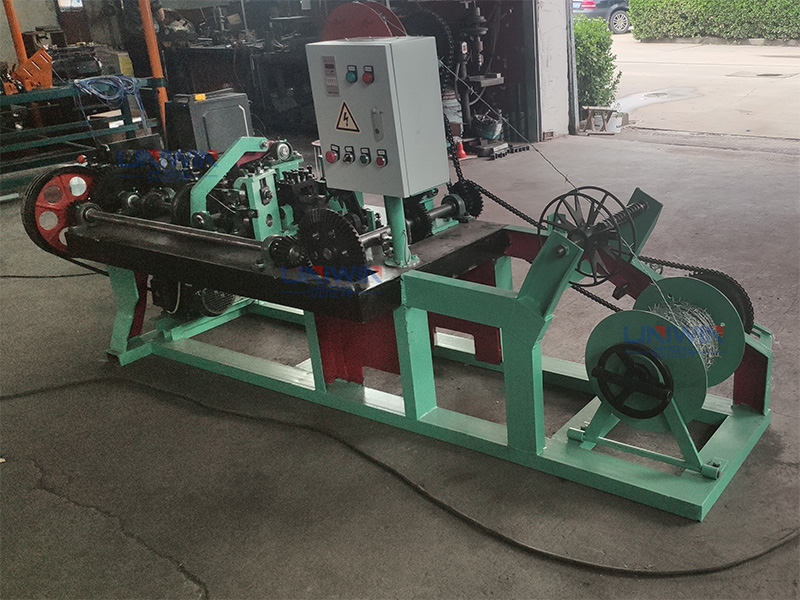

Automatic Nail Manufacturing Machine Taiwan Technology

Our company has established business relationship since 1985 with tanwan nail making equipment companies to produce the high speed nail making machine. We have been at the forefront of the nail industry these 30 years. We are dedicated to establish the national brand and we are always improving our technical and upgrade our machines to meet the needs of the market and clients.

Technical parameters and main configurations of 712 model wire nail making machine:

- Maximum Nail length: 60mm, the maximum outer diameter nail: 2.8mm

- the number of strokes per minute: 360 rpm, motor power: 2.2KW

- Noise :60 db, total weight :1250kg

- Dimensions: 1650*1150*1000mm

- Main Cabinet Material: QT50-5 main cabinet Base Material: HT200

- Main Crankshaft Material: 40cr forged (high frequency heat treatment after machining ) side of the crankshaft Material :40cr forged (high frequency heat treatment after machining )

- Central main slider: 42crmo forged (after processing hard nitride ) material scissors slider :40cr forged (after processing hard nitride )

- Dalian spindle pole material: ZG310-570 (high-frequency heat treatment after machining )

- Small rod side of the shaft material: ZG310-570 (high-frequency heat treatment after machining )

- Gear: Gleason helical teeth (Origin :Taiwan)

- Fixed block -oriented material (scissors above the slider) :94 copper dovetail mounting block material (feed slider on both sides ) :94 Copper

- Main bearing material:copper side bearing 663 Material: 663 Copper wire semicircle block material: copper 94

- Bearing Brand :Harbin Bearing Motor Brand:Lu,an Jianghuai

- Main Crankshaft Material :. 40cr forged ( high frequency heat treatment after machining ) side of the crankshaft Material : 40cr forged ( high frequency heat treatment after machining )

- Central main slider :. 42crmo forged ( after processing hard nitride ) material scissors slider : 40cr forged ( after processing hard nitride )

- Dalian spindle pole material :. ZG310-570 ( high-frequency heat treatment after machining )

- Small rod side of the shaft material : ZG310-570 ( high-frequency heat treatment after machining )

- Gear: Gleason helical teeth ( Origin : Taiwan )

- Fixed block -oriented material ( scissors above the slider ) : 94 copper dovetail mounting block material ( feed slider on both sides ) : 94 Copper

- Main bearing material: copper side bearing 663 Material: 663 Copper wire semicircle block material: copper 94

- Bearing Brand : Harbin Bearing Motor Brand: Lu,an Jianghuai